Axelent Xperience

Bekijk onze oplossingen in actie

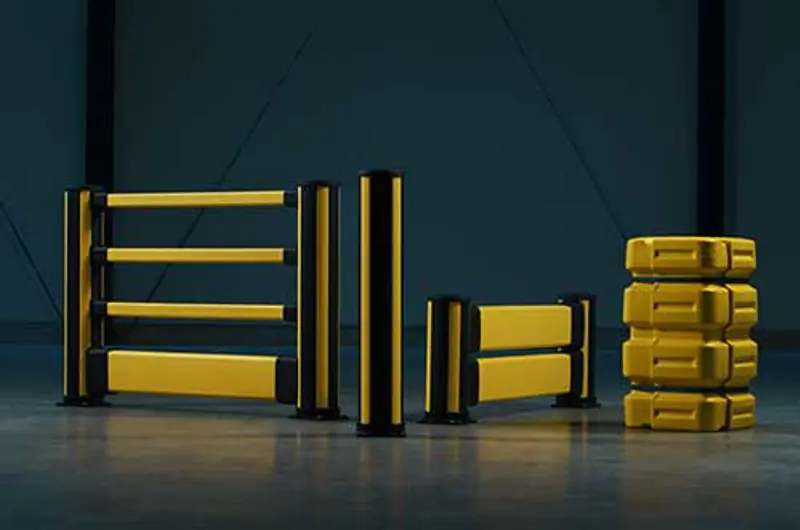

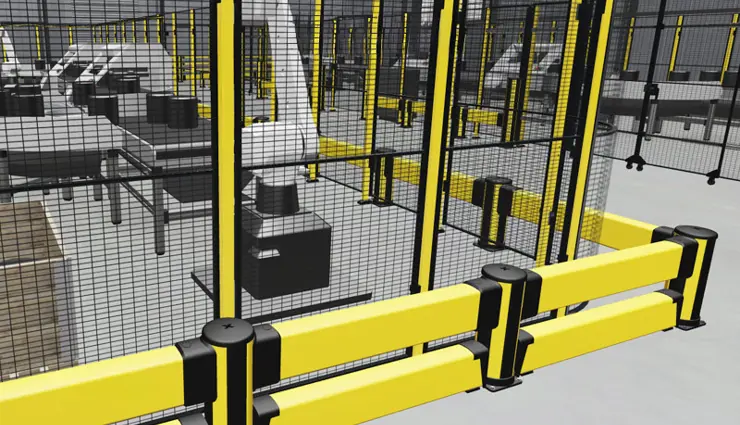

Verken de digitale showroom van Axelent om onze veiligheidsoplossingen voor magazijnen te ontdekken. Bekijk hoe modulaire beveiligingssystemen in de praktijk werken, leer van casestudy's van klanten en zie hoe onze veiligheidsoplossingen naadloos aansluiten op geautomatiseerde workflows.